Granite Machinery Component

Delivery term:The date of payment from buyers deliver within days- Price:

Negotiable

- minimum:

- Total supply:

- Delivery term:

The date of payment from buyers deliver within days

- seat:

Shandong

- Validity to:

Long-term effective

- Last update:

2023-06-25 03:33

- Browse the number:

81

- Unparalleled Ltd

-

Contact:

enpailaiou(Mr.)

-

Email:

-

Telephone:

-

Phone:

-

Area:

Shandong

-

Address:

C Zone, Binhe Business Center, No.8888 Xiaoqinghe North Road, Tianqiao District, Jinan City, Shandong Province, China.

- Website: http://www.unparalleled-group.com/ http://enpailaiou.sanjiangbio.com/

By certification [File Integrity]

By certification [File Integrity]

Product details

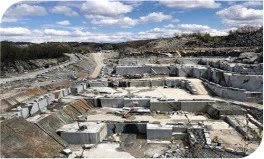

Granite Machine Components are as machine bed, machine base, machine gantry, machine bridge, machine pillar or machine air bearing to offer high precision surfaces so that precision machine can maintain high precision during working. More and more ultraprecision machines such as cmm machines, vmm machine, (video measuring machines) are choosing granite components to replace metal machine bed. Since noticing the superior characteristics of black granite, UNPARALLELED Ltd. began to produce precision granite platforms and ultra-precision granite measuring tools (precision granite square ruler, precision granite square ruler, precision granite V-block, etc.), in addition to ultra-high-precision high-end standard parts, UNPARALLELED LTD has been supplying a large number of processing of special precision granite components. Granite machine base also called granite base, granite machine bed, granite mechanical base...  Granite is an material for precision machinery - from coordinate measuring equipment to general machine construction with honing, grinding and milling, Dependingon the respective requirements, various types of granite, e.g.Jinan Black Granite, Indian Black Granite..are available.

Â

The company accepts orders for main structural parts of semiconductor-related equipment, vision and inspection equipment, and metrology equipment, etc., made of granite materials. Our company can produce ultra-large-sized precision granite components. The entire granite component can reach 12000*3000*500mm, and the length of precision granite products that can be spliced is not limited.

Unparalleled focus on manufacturing precision granite, precision ceramic, mineral casting... for decades years. UNPARALLELED Ultra-high Precision Advanced Manufacturing Solutions is specialized in manufacturing custom precision granite components for high-end precision machinery such as CMM, CNC, Laser, metrology equipment... UNPARALLELED Precision Granite is your best choice. Only UNPARALLELED will give you warranty of 1 year. And UNPARALLELED not only manufacture precision granite machine base for you, but also offer you one stop industrial solutions such as design drawings, improve the designs, purchase all parts for customers, inspection and assemble the rails and screws on precision granite machine bases...

1 High End Material---Nature Granite

UNPARALLELED will choose granite material not marble.

We will choose the best nature granite material to manufacture custom mechanical components for High-end precision machinery. UNPARALLED Granite materials are with stable physical characteristics and nice physical properties. UNPARALLELED Granite material' density will be high than 3050kg/m3. Marble' physical properties are less than granite.

Â

2 Ultra-high Precision Hand Lapping

Each precision granite component is manufactured by hand lapping. UNPARALLELED has the most advanced manufacturing equipment and inspection equipment, and enforces the most strict Quality Control system.

Â

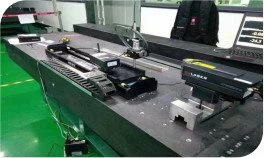

3 Authoritative Inspection Report

UNPARALLELIED has advanced measuring devices such electric level, Laser interferometer & cmm machines and so on. We will offer authoritative inspection report for each granite component before shipping.

Â

|

BRAND |

UNPARALLELED |

MATERIAL |

Nature Granite |

|

APPLICATION |

Metrology, CNC, Laser... |

DENSITY |

≈3070kg/m3 |

|

CONDITION |

NEW CUSTOM |

COLOR |

Pure Black |

|

ORIGIN |

JiNan, CHINA |

PRECISION |

1 μm or higher |

|

WARRANTY |

1 YEAR |

STANDARD |

DIN, GB, ASME,JIS... |

|

PACKAGING |

Custom Export Package |

CERTIFICATE |

ISO9001, CE... |

|

PAYMENT ITEM |

T/T, L/C... |

KEY WORD |

Granite Component, Precision Granite |

|

MATERIAL ORIGIN |

Jinan, China; India; South Afica |

TECHNICAL SUPPORT |

Inpsection& Calibration& Assembly |

|

PRICE |

EXW, FOB, CIF, DAP, CPT... |

SERVICE |

Design drawings |

Â

Laser Interferometer

Electric Level

Roughness Meter

Vernier Caliper

Dial Gauge

Inductance Micrometer

1. Who are we?

UNPARALLELED starts 1896, has the most advanced measuring and inspection equipment. We can manufacture a variety of ultra-high precision mechanical components for high-end machines.

Â

2. What material does UNPRALLELED choose?

Black Granite. UNPARALLELED has tested many kinds of granite material in all over the world.

Â

3. Why should you buy from us?

Only UNPARALLELED can offer warranty of 1 year for the precision of each product.

Â

4. We want to purchase one set this time, is this ok?

Of course. We can manufacture custom precision granite machine components according to your drawings. MOQ is 1 piece.

Â

5. Does UNPARALLELED offer Authoritative Inspection Report?Â

UNPARALLELED has the most advanced measuring devices.

UNPARALLELED all measuring equipment have the calibration report.Â

Â

6. Is there an industry standard for surface plate accuracy?

Most manufacturers use DIN Standard, GB Standard, ASME B89.3.7-2013 or Federal Specification GGG-P-463c (Granite Surface Plates) as a basis for their specifications. You can access the DIN, GB, JIS, ASME spec or the GGG-P-463c from our Engineering department. You send email to: info@unparalleled-group.com

Â

7. What's The Granite Mechanical Components? & How To Choose Real Granite Not Marble?

Â

Granite was used as a building and ornamental stone. With the continuous development of science and technology, stone application has been brought into a new field, and it has a wider application. Using high quality granite stone granite components machining and hand-made fine grinding, occupies an important position in the construction, decoration, decoration, metallurgy, machinery manufacturing, precision measuring tools, test equipment, finishing equipment etc...

Â

Granite mechanical components are made of high quality black natural granite. UNPARALLELED searched many mines in the world, and found two kinds of black granite with stable physical properties and beautiful cut color --- Jinan Black Granite and Indian M10 Black granite. These two types of granite have stable physical properties and a density of 3030-3100kg/m3, which is a rare material for making precision mechanical components.

The material chosen by UNPARALLELED is granite not marble. At present, many manufacturers choose low-priced marble to deceive customers. Because customers do not understand the difference between granite and marble, and it is difficult to distinguish from the color of the stone, most customers still do not understand this product. Many customers may have questions, marble and granite are both stones, what is the difference? The difference can be big:

-

1. In terms of price, the price of granite is very expensive, and the price of marble is very cheap.

-

2. Granite is hard and marble is soft.

-

3. The physical properties of granite are stable and can maintain high precision; the physical properties of marble are not as good as granite, and the precision is easy to change.. .

In summary, granite is a good material for making precision mechanical components. Many manufacturers use cheap marble to pretend to be granite, thereby earning high profits. Many customers will ask how to choose granite instead of marble?

-

1. Ask the supplier to provide a stone analysis report.

-

2. Look for the UNPARALLELED brand.

-

3. The customer is required to provide corresponding stone photos, and the stone surface is not oiled or painted, and the color of the stone itself is retained. The color of the marble surface after manual grinding is different from that of the ground granite surface.

More information please contact: info@unparalleled-group.com

http://www.unparalleled-group.com/

-

Galvanized Hexagonal Wire Netting

Galvanized Hexagonal Wire Netting

price: Negotiable

-

Coat Interlining

Coat Interlining

price: Negotiable

-

Best Baby Diaper

Best Baby Diaper

price: Negotiable

-

Custom CNC Machining

Custom CNC Machining

price: Negotiable

-

Butterfly Catalyst Carrier

Butterfly Catalyst Carrier

price: Negotiable

-

48*76mm Scaffolding Rotating Clamp

48*76mm Scaffolding Rotating Clamp

price: Negotiable